Le Master en Conservation-restauration de la HE-Arc est destiné aux futur·es professionnel·les souhaitant approfondir leurs connaissances en conservation. Il met l'accent sur la mise en oeuvre des mesures curatives des objets patrimoniaux.

Destinés aux titulaires d'un Bachelor, les Masters HES-SO permettent d’élargir les compétences et soutiennent la progression professionnelle. Ils représentent un passage de la pratique vers des activités plus réflexives de recherche et d'enseignement ou de conduite de projet. Ils sont également des prérequis à l’obtention d’un doctorat en HES, en collaboration avec des partenaires universitaires suisses et étrangers.

- Design et Arts visuels 6

- Economie et Services 5

- Ingénierie et Architecture 5

- Musique et Arts de la scène 6

- Santé 3

- Travail social 2

- Interdisciplinaire 1

Le Master en Design est professionnalisant, en lien direct avec les exigences contemporaines, et prend en compte le contexte international dans lequel s'inscrit le design.

L’ECAL et la HEAD – Genève ont chacune trois orientations dans cette filière. Le contenu pédagogique spécifique aux orientations repose sur les compétences et l’identité propre

Cette formation vous offre l'opportunité unique d'explorer le monde de l'innovation à travers un programme interdisciplinaire et immersif. Conçu pour former les innovateurs et innovatrices de demain, ce programme vous permettra de concevoir des produits et des services novateurs tout en répondant aux défis sociaux, économiques et environnementaux actuels.

Le Master en Architecture d'intérieur de la HEAD - Genève est un programme professionnel qui prépare ses étudiant·es à maîtriser la diversification progressive des intérieurs dans le monde contemporain. Il se caractérise par des approches transdisciplinaires, du design aux arts visuels, de la culture audiovisuelle à la réalité numérique.

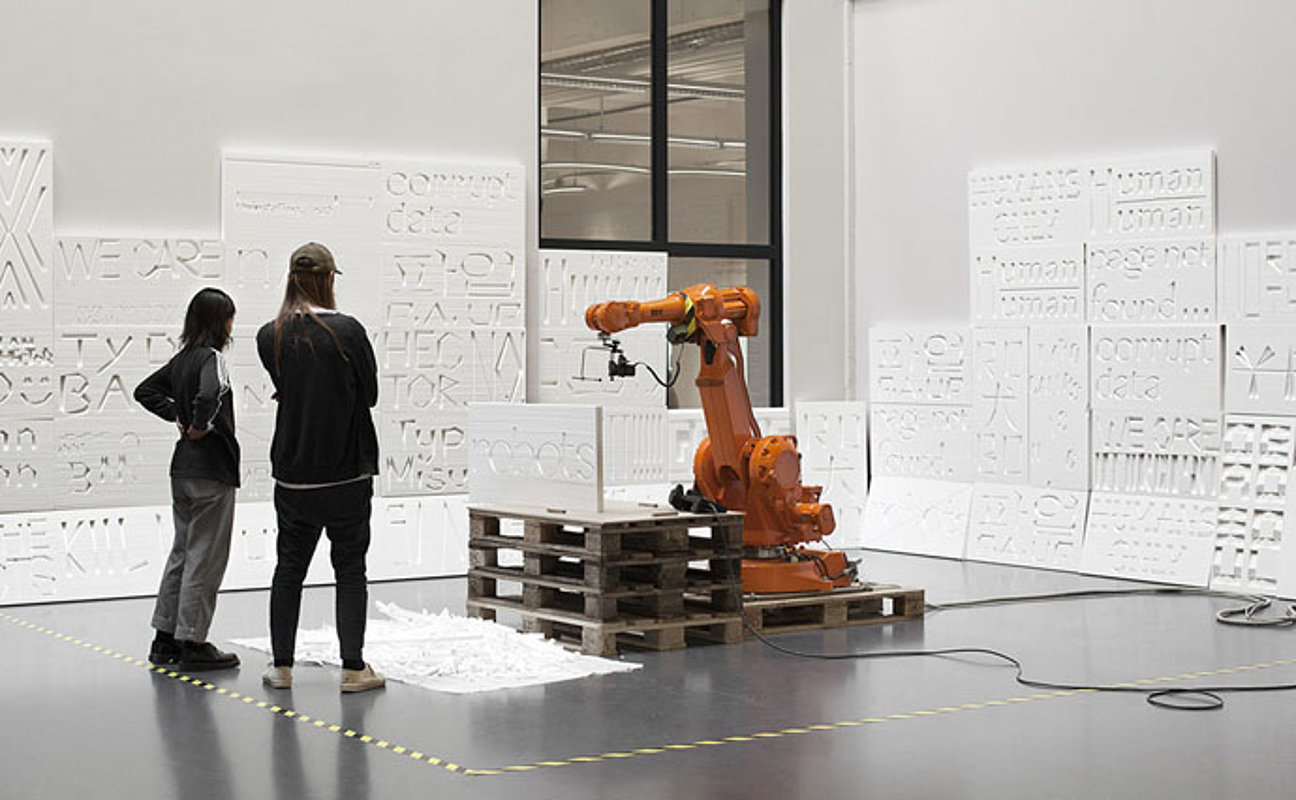

L’art contemporain est un champ d’activités riche dans lequel les professions et les spécialisations sont continuellement redéfinies. Le Master en Arts visuels s’adresse à des étudiant·es titulaires d’un Bachelor, passionné·es par la pratique artistique ou une approche plus théorique et curatoriale.

L’ECAL, l’EDHEA et la HEAD – Genève proposent des orientations dans cette filière. Le contenu pédagogique spécifique aux orientations repose sur les compétences et l’identité

Le Master en Cinéma permet de développer une vision cinématographique personnelle, comprendre le processus de fabrication d’un film et en saisir les dimensions de production afin d’ouvrir en fin de parcours les voies d’une intégration dans les milieux professionnels.

L’ECAL et la HEAD – Genève offrent conjointement cette formation en s’appuyant sur leur identité spécifique.

Le Master of Science en Business Administration (MSc BA) permet d’approfondir les connaissances en management acquises en Bachelor et de se spécialiser dans des champs de compétences en forte croissance.

En partenariat avec les hautes écoles du domaine Economie et Services, quatre Orientations sont proposées :

Nous vous proposons trois séances d'information en ligne:

À l'issue de chacune de ces présentations d'une durée d'environ 45 minutes, des canaux par orientations seront organisés afin que vous puissiez poser des questions aux étudiant·es actif·ves au sein du Master. L'inscription est obligatoire. >> Lien Nous nous tenons également à disposition pour toute question par e-mail ou par téléphone (+ 41 58 900 00 00). |

EHL’s Master of Science in Global Hospitality Business prepares graduates to lead businesses and teams into the future of the industry. Over the course of three semesters, on three continents, students learn to manage the complexity of worldwide operations with the local touch that makes for exceptional customer experiences. It is offered jointly by EHL (Lausanne campus), Hong Kong Polytechnic University and Conrad N. Hilton College, University of Houston, Texas, USA.

Cette formation vous offre l'opportunité unique d'explorer le monde de l'innovation à travers un programme interdisciplinaire et immersif. Conçu pour former les innovateurs et innovatrices de demain, ce programme vous permettra de concevoir des produits et des services novateurs tout en répondant aux défis sociaux, économiques et environnementaux actuels.

The hospitality industry is changing at pace. Businesses in the sector are implementing new operating structures to adjust to global challenges and are preparing hospitality for a new future. The need for skilled managers to bring innovation to the industry is paramount. Our program primes you to succeed in this environment through an in-depth study of current hospitality management trends and best practice.

Multiplication des flux d’information, prolifération de données, big data, gestion de l'information stratégique... Ce Master met un accent particulier sur la pratique et apporte des connaissances solides pour faire de vous des futur·es cadres supérieur·es et responsables de projets en gestion de l’information et des données.

Le Joint Master of Arts en Architecture (JMA) est une formation proposée conjointement par les filières d'architecture de la Haute école d'ingénierie et d'architecture Fribourg - HEIA-FR, de l'HEPIA - Haute école du paysage, d'ingénierie et d'architecture de Genève (HEPIA) et de la Haute école spécialisée bernoise (BFH).

Ce Master conjoint HES-SO-UNIGE offre une formation pointue dans les domaines de l’urbanisme, de la géomatique, de l’architecture du paysage et de l’aménagement du territoire tant au Nord qu’au Sud.

Le but du Master of Science in Engineering (MSE) est de former de futurs ingénieures et ingénieurs capables de prendre la responsabilité de projets d'envergure dans les domaines technologiques et de l'ingénierie civile.

Les 7 Orientations suivantes sont proposées :

Cette formation vous offre l'opportunité unique d'explorer le monde de l'innovation à travers un programme interdisciplinaire et immersif. Conçu pour former les innovateurs et innovatrices de demain, ce programme vous permettra de concevoir des produits et des services novateurs tout en répondant aux défis sociaux, économiques et environnementaux actuels.

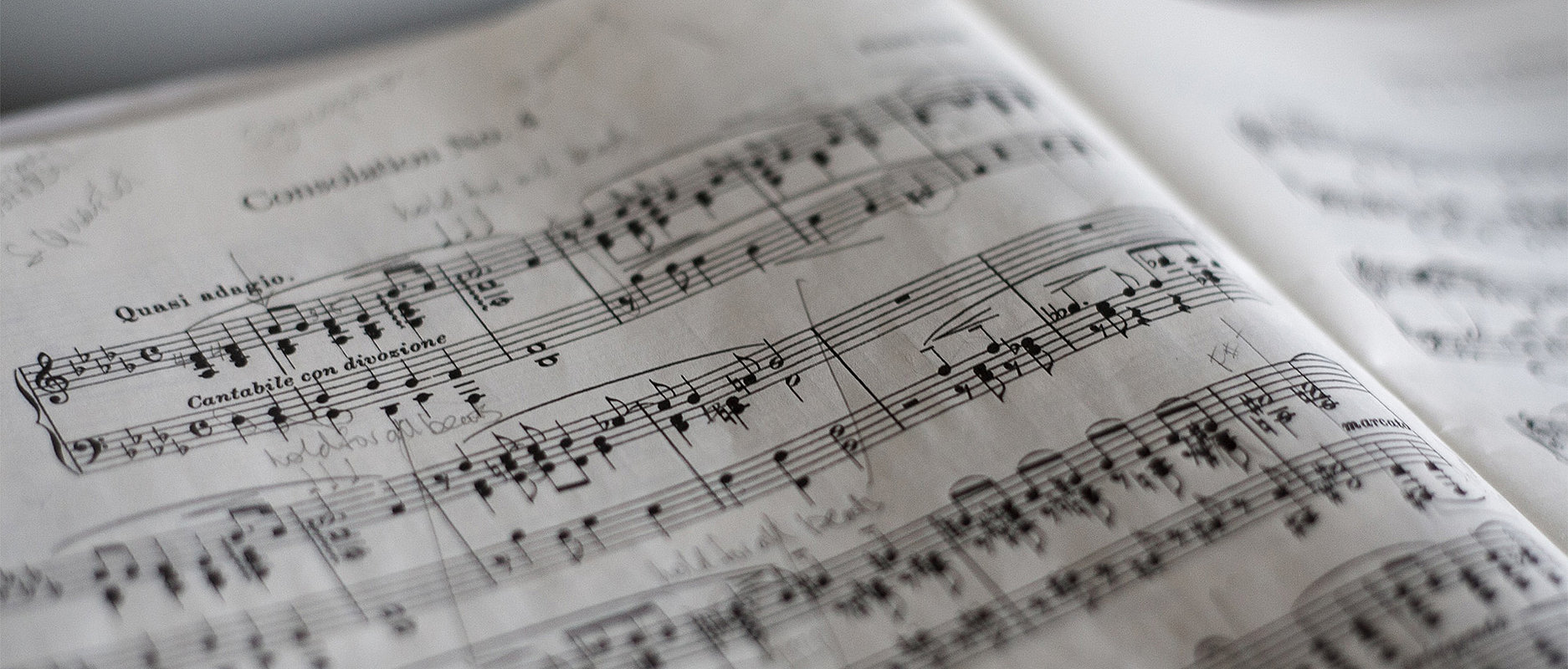

Le Master of Arts en composition et théorie musicale prépare à une activité professionnelle axée sur la création en tant que compositeur et/ou une activité pédagogique ou scientifique axée autour de la théorie de la musique.

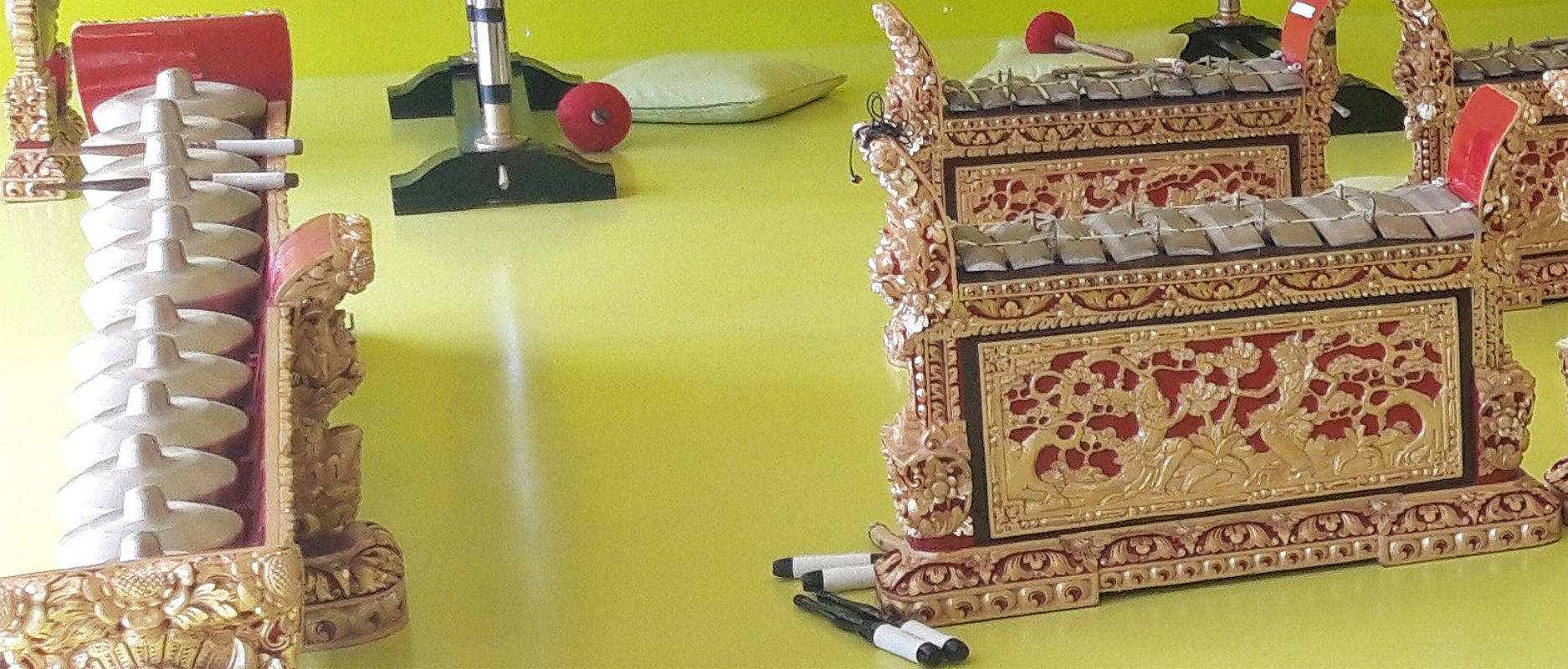

L’ethnomusicologie traite de la musique et de ses pratiques, en Occident et au-delà, en mettant l’accent en particulier sur ses dimensions culturelles, sociales, rituelles ou encore de transmission.

Le Master of Arts en interprétation musicale prépare aux métiers de musicien interprète à un haut niveau de formation artistique, permettant l'accès au marché du travail comme artiste indépendant ou exerçant au sein d'institutions de production : orchestres, maisons d'opéra.

La filière du MA en interprétation musicale spécialisée est conçue comme une filière de haute exigence, préparant un nombre restreint d'étudiants montrant des capacités exceptionnelles à une activité artistique au plus haut niveau.

Orienté vers la recherche artistique et ses applications, ce master s'inscrit dans un contexte pratique de création et de métissage des disciplines. Il comprend deux orientations, une en Mise en scène et une en Scénographie, partageant un fort tronc commun.

La filière de Master of Arts en pédagogie musicale prépare aux métiers d'enseignement de la musique, au sein des écoles de musique, des conservatoires jusqu'au niveau Haute école de musique, ou de l'école publique au niveau secondaire II. Cette activité pédagogique constitue un élément essentiel du portfolio professionnel du musicien.

L’ostéopathie est une profession de la santé dont les méthodes de traitement, basées sur des techniques manuelles, sont à la fois préventives et curatives. La formation Master of Science HES-SO en Ostéopathie est réservée aux diplômées et diplômés d’un Bachelor HES-SO en Ostéopathie.

Un Master interprofessionnel conjoint avec l'Université de Lausanne (UNIL) au service de la qualité des soins avec cinq Orientations :

- Ergothérapie

- Nutrition et diététique

- Physiothérapie

- Sage-femme

- Technique en radiologie médicale

Il s'adresse aux titulaires d’un Bachelor de l’une de ces professions.

L'Université de Lausanne (UNIL) et la Haute école spécialisée de Suisse occidentale (HES-SO) proposent un Master conjoint ès sciences infirmières (MScSI).

Cette formation est placée sous la responsabilité de l’Institut universitaire de formation et de recherche en soins (IUFRS) au sein de la Faculté de biologie et de médecine de l’Université de Lausanne.

Le Master en Psychomotricité forme aux responsabilités cliniques des thérapeutes en psychomotricité, expert·es du corps et de son rôle dans le développement et le fonctionnement psychique, émotionnel et social des personnes.

De l'analyse à l'intervention, devenir expert·e en travail social.

Les hautes écoles de travail social (HETS) de Suisse romande et du Tessin s'associent pour proposer un Master à la pointe de la recherche.

Cette formation vous offre l'opportunité unique d'explorer le monde de l'innovation à travers un programme interdisciplinaire et immersif. Conçu pour former les innovateurs et innovatrices de demain, ce programme vous permettra de concevoir des produits et des services novateurs tout en répondant aux défis sociaux, économiques et environnementaux actuels.